ALUCOBOND® PLUS

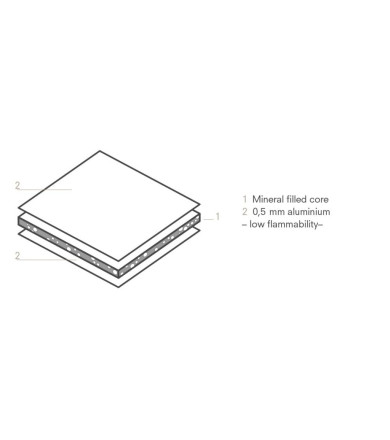

ALUCOBOND® PLUS is a composite panel consisting of two aluminium cover sheets and a mineral-filled polymer core. The superb properties of this material boost one’s inspiration and offer architecture a whole new range of solutions – whether your project is a private home, a public building, a corporate headquarter and offices, or a trading or industrial complex – or if your organisation wants to create a new image-building Corporate Design – whether for petrol stations, car showrooms, banks or supermarkets. ALUCOBOND® even offers a multitude of application options in the Transport & Industry sector.

- Description

PRODUCT PROPERTIES

ALUCOBOND® PLUS compared with solid aluminium

Required thickness and actual weights of panels with same rigidity

| ALUCOBOND® PLUS | Aluminium | ||||

| Rigidity (E·J) | Section modulus | Thickness | Weight | Thickness | Weight |

| 1250 kN cm²/m | 1.25 cm³/m | 3 mm | 5.9 kg/m² | 2.7 mm | 7.3 kg/m² |

| 2400 kN cm²/m | 1.75 cm³/m | 4 mm | 7.6 kg/m² | 3.3 mm | 8.9 kg/m² |

PRODUCT RANGE

ALUCOBOND® PLUS

Thickness: 3/4mm (6mm on request)

| Width [mm] | 1000 | 1250 | 1500 | 1575 | 1750 |

|---|---|---|---|---|---|

| Length [mm] | 2000-6800 | 2000-6800 | 2000-6800 | 2000-6800 | 2000-6800 |

| Solid Colours | |||||

| Metallic Colours | |||||

| Spectra & sparkling | |||||

| Anodized Look | |||||

| NaturAL | |||||

| ALUCOBOND® Legno – premium wood | |||||

| Vintage | |||||

| Façade design – individual décor | |||||

| Urban | |||||

| Terra | |||||

| Anodized * | |||||

| Mill Finish |

Dimensional Tolerances (Standard)

Due to manufacturing, a displacement of the cover sheets sidewise at the panel edges up to 2 mm is possible.

Thickness: ± 0,2 mm

(mill-finish | stove lacquered | anodized)

Width: – 0 / + 4 mm

Lengths: 2000 – 4000 mm; – 0 / + 6 mm

Lengths: 4001 – 6800 mm; – 0 / + 10 mm

Colours and surfaces

More colours and surfaces are available upon request.

They are subject to our minimum quantities.

* Anodized according to DIN 17611. All anodized ALUCOBOND® PLUS composite panels have contact lines (about 25 mm width) on their short sides. For panel lengths of more than 3500 mm, the composite panels have contact lines (about 2-3 mm width) on their long sides. Maximum panel length 6500 mm. Please take this into consideration when dimensioning the panels.

TECHNICAL DATA

| Thickness | Standards | Unit | 3 mm | 4 mm | |

| Thickness of Aluminium Layers | [mm] | 0.5 | |||

| Weight | [kg/m²] | 5.9 | 7.6 | ||

| Width | [mm] | 1000 / 1250 / 1500 (1575 / 1750) | |||

| Technical properties | |||||

| Section modulus | W | DIN 53293 | [cm³/m] | 1.25 | 1.75 |

| Rigidity | E·J | DIN 53293 | [kNcm²/m] | 1250 | 2400 |

| Alloy / Temper of Aluminium Layers | EN 573-3 EN 515 | EN AW 5005A (AIMg1) H22 / H42 | |||

| Modulus of Elasticity | EN 1999 1-1 | [N/mm²] | 70.000 | ||

| Tensile Strength of Aluminium | EN 485-2 | [N/mm²] | Rm ? 130 | ||

| 0.2 % Proof Stress | EN 485-2 | [N/mm²] | Rp0,2 ? 90 | ||

| Elongation | EN 485-2 | [%] | A50 ? 5 | ||

| Linear Thermal Expansion | EN 1999 1-1 | 2,4 mm/m at 100ºC temperature difference | |||

| Core | |||||

| Mineral filled polymer | |||||

| Surface | |||||

| Lacquering | Coil Coating Fluorocarbon (e.g. PVDF) | ||||

| Gloss (initial value) | EN 13523-2 | [%] | 30-80 | ||

| Pencil Hardness | EN 13523-4 | HB-F | |||

| Acoustical Properties | |||||

| Sound Absorption Factor | ?s | ISO 354 | 0.05 | ||

| Sound Transmission Loss | Rw | ISO 717-1 | [dB] | ? 25 | |

| Thermal Properties | |||||

| Thermal Resistance | R | DIN 52612 | [m²K/W] | 0.007 | 0.009 |

| Thermal conductivity | ? | DIN 52612 | [W/mK] | 0.49 | 0.44 |

| Heat transition coefficient | U | DIN 52612 | [W/m²K | 5.68 | 5.58 |

| Temperature Resistance | [ºC] | -50 to +80 | |||

Wind load and permissible panel sizes

In Germany, the dimensioning of ALUCOBOND® façade systems is regulated by the general building inspectorate approval (abZ) No. Z-10.3-774. In the Technical Extras section, you can find this and other documents, including load tables, dimensioning aids and various design examples.

FIRE CLASSIFICATION

| Country | Test accord. to … | Classification |

| Australia | AS ISO 9705 AS 1530.3 Indices EN 13501-1 | Group 1 material SMOGR A 1.385 m2 / s2 0 (ignitibility) 0 (flame spread) 0 (heat evolved) 0-1 (smoke developed) B-s1, d0 |

Brand